In February, the magazine Dentistry Today published an article that proclaimed 2021 as the year of 3D printing in dentistry. The article evinces an optimism about the technology’s ability to help professionals in a variety of ways, particularly with restorative dentistry. The writer; Dr. Elisa Praderi, a clinical protocols manager at Formlabs Dental; points to new developments in materials science as an indicator of 3D printing's potential for dental practices: "New materials unlock new applications, from clear aligners to dentures to crowns and bridges.”

It’s understandable Dr. Praderi would tout the usefulness of 3D printing, given that she works for a 3D printing company. However, 3D printing isn’t yet in wide use among dental practices. Let’s explore the technology to see if it’s something dentists can take advantage of.

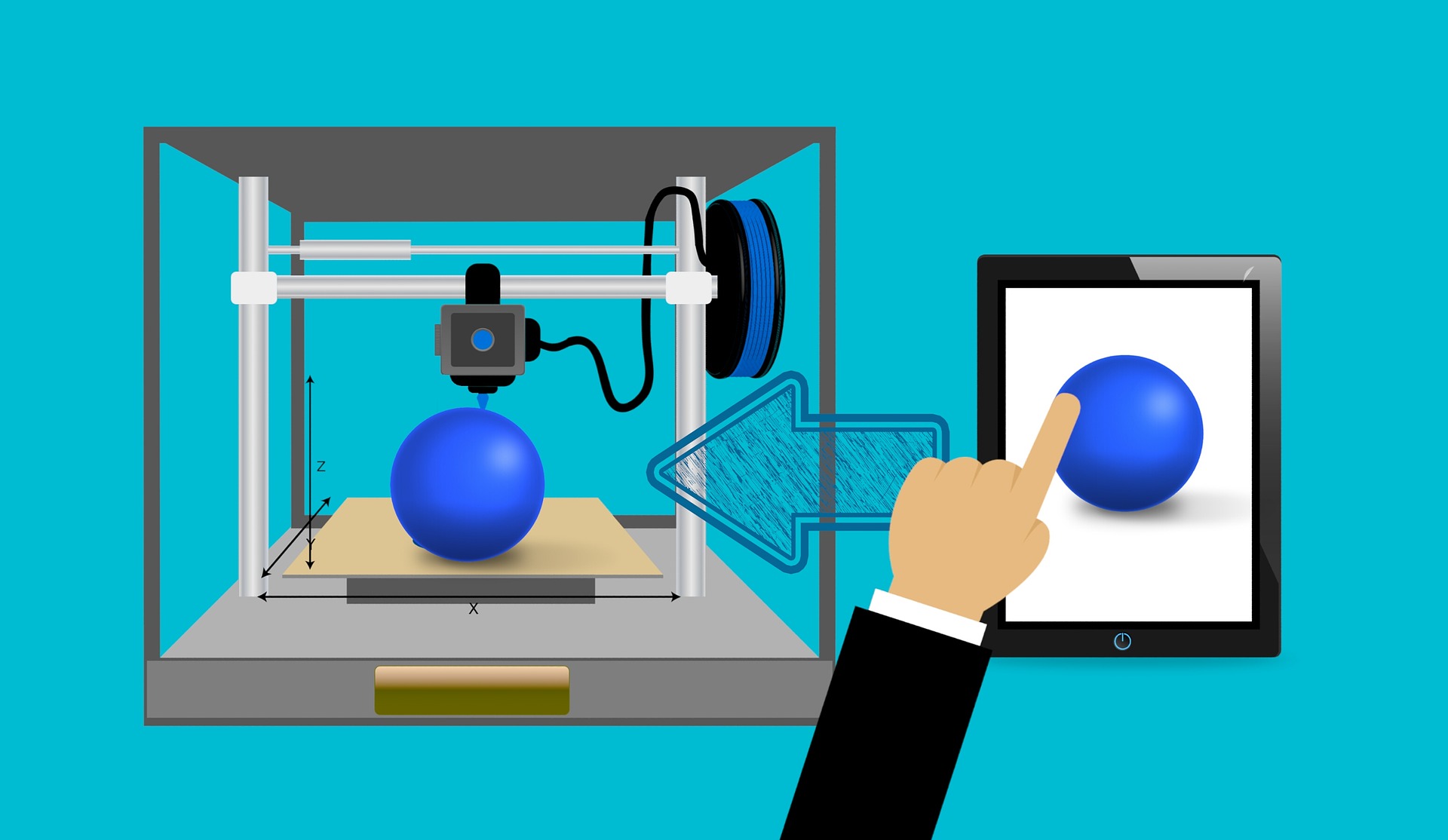

3D Printing

In brief, 3D printers are machines that can automatically manufacture a variety of physical objects and tools using digital diagram files. A file containing a kind of blueprint or diagram of an appliance is loaded into the printer, which then uses advanced computer software and robotic apertures to produce the object. Depending on what you’re making, the printing process can take anywhere from a few minutes to several days. 3D printers have successfully crafted everything from car parts to toys to camera lenses to guns. Since dental care often entails the crafting of special materials—such as night guards, dentures, bridges, and so on—it makes sense that dentists could take advantage of the technology.

3D Printing for Dentists

Historically, orthodontic and dental implants have either been made by human technicians or, more recently, specialized CAD/CAM milling machines. In either case, the investment for dental crafting is steep. A technician’s annual salary can run as high as $65,000. Milling machines, meanwhile, can reach well into the six-figure range for higher end machines. And that’s before you factor in expenses for maintenance, space, and insurance.

By contrast, 3D printers don’t require large labs to produce similar appliances. While there is an upfront cost of purchasing the printer, often around $20,000, they’re much less costly to maintain than a human technician or a milling machine. Furthermore, 3D printers can manufacture multiple appliances at once, increasing output while cutting costs. That fact that 3D printers are so effective at reducing expenses may eventually make them a regular sight in dentists’ offices across the country.

Still, there are some limitations to 3D printing. Like any manufacturing process, printers need raw materials to produce, and, considering the present stresses on global supply chains, the possibility for material shortages need to be considered. In addition, 3D printers consume a lot of energy compared to other, more common equipment you might find in a dental office. Even if an office’s costs are cut in labor and space, they may incur new expenses elsewhere. It’s also worth mentioning that 3D printers make use of CAD software in the same way that milling machines do, so you’ll still need to invest in a reliable CAD/CAM software. Lastly, due to the way that printing apertures manufacture appliances, there are limitations to the complexity of products a printer can fashion. To be fair, this doesn’t appear to be an issue with dental appliances—there are currently several 3D printing companies that specialize in dental crafting—, but offices may still need to employ human technicians or alternative technologies from time to time.

3D printing is one of the many exciting technological frontiers today. If you’re interested in speaking with reliable tech experts on the costs and benefits of integrating 3D printing technology into your practice, reach out to Titan Tech to schedule a free consultation.

And come back next week for more tech news.