At the risk of rehashing old news, the world is currently in the throes of a computer chip shortage, due in large part to stresses put on global supply chains by the COVID-19 pandemic. Stephen Shankland, a staff writer at CNET, wrote a helpful summary about the issue this week. The article describes not only the shortage itself but also how it has spurred many in the manufacturing sector to reconsider their reliance on foreign-sourced chip manufacturing and raw materials, particularly from China and South Korea. "Overall, the chip shortage is shining a new spotlight on the state of US manufacturing and how much of it has moved out of the country."

But what are tech firms doing in the face of this? Let's explore some of the strategies that U.S. technology companies and manufacturers are using to address these new pressures.

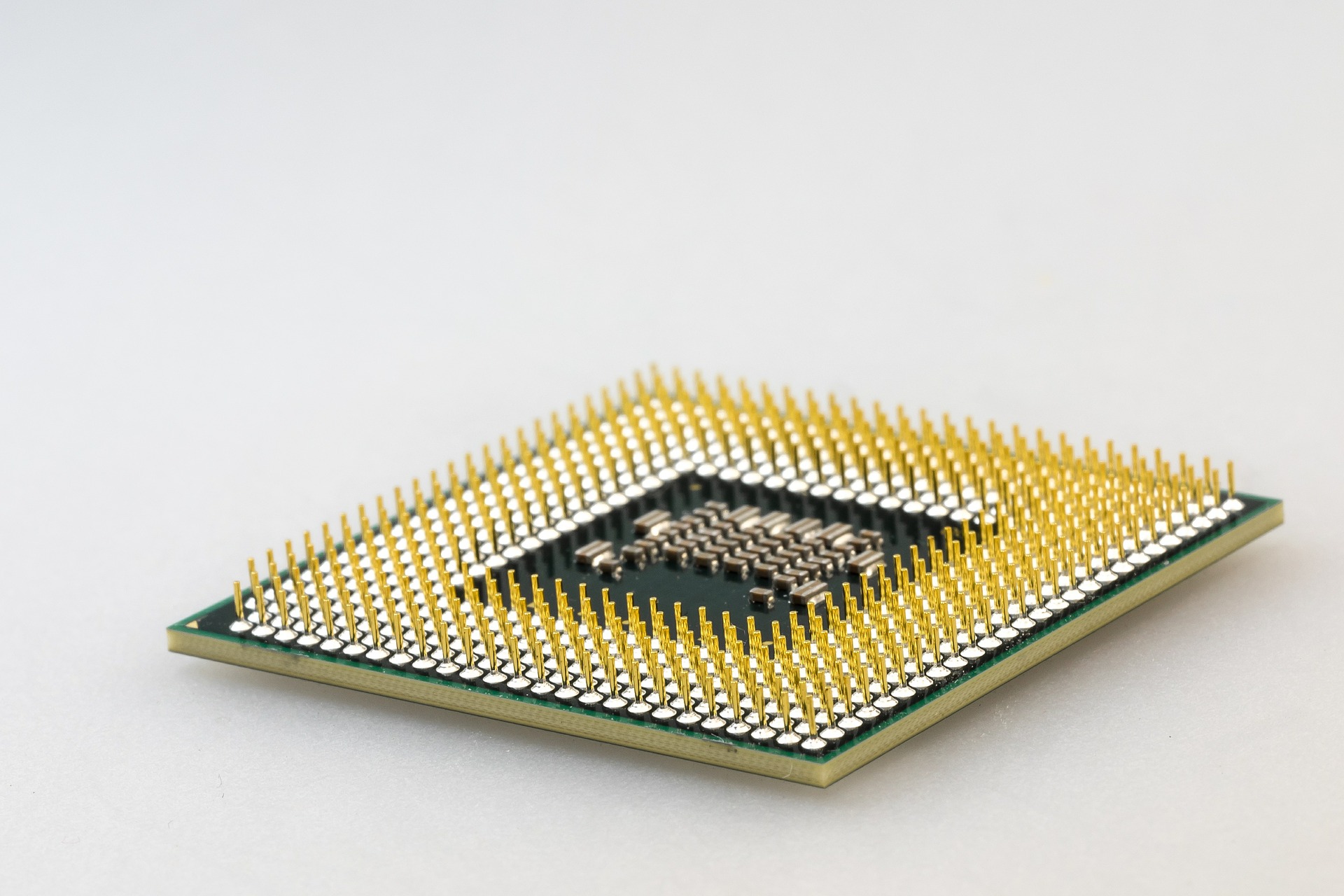

Fabulous Fabs

In 2020, The House of Representatives introduced the CHIPS for America Act, which allocated roughly $52 billion in government subsidies for domestic chip manufacturing. The House has yet to vote on the act. In addition, the Senate passed the United States Innovation and Competition Act in June of 2021, which allocated $10 billion towards specialized chip fabrication facilities, or fabs for short.

On top of potential subsidies, many companies plan to allocate more of their own money toward building fabs in the United States. For example, Intel has already spent $23.5 billion this year to invest in new fabs, according to Shankland's article. Meanwhile Samsung, a South Korean company with production facilities in the States, plans to spend $145 billion on fab building through 2030.

Increasing the number of domestic fabs would certainly go a long way in relieving the shortage, as they would decrease the U.S. market's reliance of foreign goods that might get lost along the pandemic-beset supply chain. Still, it may be too early in the investment cycle to know how well both U.S. manufacturers--and foreign manufacturers whose production facilities are housed state-side, like Samsung--will be able to compete, especially when foreign firms are also investing in their own new fabrication facilities.

Pivoting in the Pandemic

The future of the pandemic and international supply chains is uncertain. However, if there is one silver lining to the COVID-19 outbreak, it's that it has forced many manufacturers to take a hard, honest look at the efficacy of their business models. Practices that were once commonplace, from so-called just in time inventory strategies to relying on singular or non-diversified suppliers, have emerged as liabilities in the wake of pandemic.

Technology will undoubtedly play a role in finding our way out of these turbulent times. Increased automation and digitization can curb some of the negative effects of these circumstances but only when implemented properly. After all, tech is as reliant on the supply chain as anything else, so simply investing in new equipment or the hottest tech trend may not be beneficial, especially if you haven't done your homework.

As such, it always helps to have an advisor to guide you through assessing your operations and then planning how to use technology in a way that's both efficient and cost-effective. If you'd like to learn more on how Titan Tech can help, use their contact form to schedule a free consultation.

And stay tuned for more tech news.